Used Forklift Inspections You Can Bank On

A safe and well-maintained forklift is a profitable forklift

After each inspection, we provide a comprehensive report outlining what parts or components are showing signs of wear, when we recommend replacing them, and what it costs to perform the repair before it’s too late.

Showing signs of wear but is still safe and does not need to be replaced yet

During our inspection, we will note any parts that are beginning to show signs of wear and tear but do not yet require service or replacement. We’ll make sure to thoroughly re-inspect these on your next visit.

Should be replaced now to avoid further damage or possible injury

The time has come to replace the parts that we’ve identified as failing. This will prevent further damage to the part and surrounding components, lost time and wages, and the possibility of workplace injuries.

Catastrophic failure and likely collateral damage to other components

Don’t wait to get to this stage. At this point, the parts have completely failed during normal operation and are no longer serviceable and the forklift is down. Your forklift is now costing you money and potentially lost time and wages.

Frequently asked questions

Why is a used forklift inspection important?

Your Subtitle Goes Here

Adding a forklift to your fleet, even if it’s a used one, is a huge investment. Make sure you’re spending your money wisely and get peace of mind with a forklift inspection. We go way beyond just the work record and can help catch hidden issues before you buy.

What’s included in the inspection checklist?

Your Subtitle Goes Here

We do a comprehensive inspection that includes:

-

- Forks

- Mast and mast rails

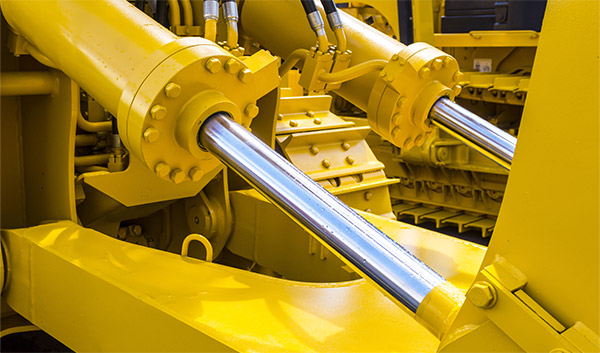

- Lift chains and cylinders

- Frame, cowling, and canopy

- Cab and controls

- Engine

- Exhaust guard and counterweights

What’s the difference between used inspections and regular inspections?

Your Subtitle Goes Here

While your forklift operators probably do some kind of daily checks on your forklifts, a used forklift inspection is much more comprehensive. It’s also different from a maintenance inspection. We take the time to assess all aspects of the forklift and identify any issues, so you can get a fair price.

Our services

200-Hour Maintenance

Every forklift should have regular maintenance after 200 hours of use. Of course, if you notice any issues before then, you should always have your forklift serviced as soon as possible.

Used Forklift Inspections

Buying a used forklift can be a daunting task. Take away the guesswork with a used forklift inspection, which will tell you the true condition of the forklift.

Normal Operation Tests

During our inspection, we’ll perform normal operation tests. We’ll make sure the forklift is ready to handle your day-to-day operations, whatever that means for you.

Electric Battery Tests

If you’re purchasing an electric forklift, we’ll perform specific tests. This includes an electric battery test to make sure the forklift can recharge and maintain charge properly.

Hydraulic System

Buying a used forklift can be a daunting task. Take away the guesswork with a used forklift inspection, which will tell you the true condition of the forklift.

Brakes & Steering

Brake and steering issues might be harder to miss, but we still thoroughly inspect them. We can tell you when to expect to replace your brakes and catch any other potential issues as well.

If your forklift isn’t making you money, talk to us.

A predictable forklift maintenance schedule frees up productive hours, ensures top-line profitability, and prevents unnecessary time lost and opportunity cost tied to preventable repairs. Ask us how.