Hydraulic systems are integral to many pieces of heavy machinery, and forklifts are no exception. A forklift can lift impressive amounts of weight without significant mechanical linkage by transmitting force through hydraulic fluid. But hydraulic systems still contain many essential parts, and knowing how they work is vital for keeping your forklift in safe working condition.

At HardCo, we’ve spent over three decades repairing forklifts, so we know a thing or two about the hydraulic parts on forklifts and when they need to be serviced. Read on to learn more about what makes your forklift lift, and how to make sure it keeps lifting properly for years to come. If you need a professional, please get in touch with us!

The Main Components of Hydraulic Systems

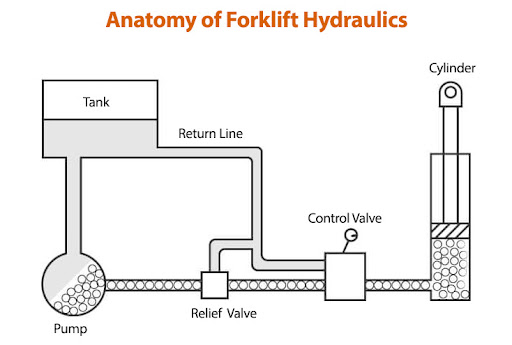

Hydraulic systems are made up of 4 main parts, although each of these depend on numerous smaller components:

Reservoir (Tank)

The primary purpose of the reservoir is to hold hydraulic fluid. It also releases air and moisture from the fluid, transfers out heat, and gives solid contaminants a place to settle.

Pump

The pump is responsible for converting mechanical energy to hydraulic energy. A motor drives the pump, which then puts pressure on the fluid within the system.

According to Pascal’s Law, increasing the pressure in one part of a confined fluid creates an equal increase at all other points of the container. This is how the action of the pump transfers force through the fluid to other parts of the system.

Valves

The control valve in a hydraulic system directs the flow of the fluid. Its job is to move hydraulic fluid to the actuators, and back to the reservoir via the system’s return lines.

In addition to a control valve, hydraulic systems must also have a relief valve to release excess pressure from the system when necessary. This is a safety feature that protects the system from over-pressurization.

Actuators

Actuators in hydraulic systems convert the hydraulic energy in the fluid back to mechanical energy, which can be used to perform different kinds of work depending on the type of actuator being used.

Forklifts typically use hydraulic cylinders as actuators, which convert hydraulic energy into linear movement. Put simply, these cylinders let your forklift move objects up and down.

What Parts Break Down the Most (& Why)?

It might surprise you to learn that the most commonly replaced forklift parts don’t involve hydraulics at all. A forklift’s forks, tires, brakes, oil, and batteries are all more prone to wear-and-tear than its hydraulic components—but that doesn’t mean your forklift’s hydraulic system can be ignored.

The hydraulic cylinders in forklifts may be damaged in several ways, including:

- Contamination of the hydraulic fluid, which can damage the cylinder’s seals and allow pressure to escape from the system.

- Damage to the piston rod or cylinder barrel, which can adversely affect the cylinder’s efficiency and impair your forklift’s performance.

- Bearing problems, which are often caused by trying to lift more weight than your forklift is designed to handle.

Hose failures in hydraulic systems have been far less dangerous since 1990 because of load holding valves, velocity fuses, and other safety features. However, proper use of your forklift—along with routine maintenance and repair—will prolong your hydraulic’s lifespan and keep the system pressurized.

How Often Should You Inspect & Service Hydraulic Systems?

The Canadian Centre for Occupational Health & Safety stipulates that all forklifts should undergo the following inspections:

- Planned maintenance inspections as recommended by the manufacturer (or every 200 hours, if no manufacturer’s recommendation exists)

- An annual planned maintenance inspection once every year or every 2000 hours (whichever comes first)

- A lifting capacity inspection, once before the forklift is used for the first time, once every time a new owner acquires it, and at regular intervals according to the manufacturer’s recommendations (but no less than once per year). This inspection determines whether the forklift can handle the maximum load identified on its nameplate.

These inspections must be carried out by properly trained and qualified maintenance technicians. Any issues they uncover must be properly addressed before continuing to operate the forklift.

Frequently Asked Questions About Hydraulic Forklifts

How Much Can a Forklift Lift?

Different forklifts are rated for different capacities. Finding out how much your forklift can handle might seem easy, since every forklift’s rated capacity is displayed on its name plate. But in reality, it’s not that simple.

A forklift’s rated capacity isn’t necessarily it’s maximum capacity (i.e. how much it can actually lift). Your forklift’s maximum capacity for any given load will depend on its placement, weight distribution, and dimensions. It changes depending on what you’re lifting.

Rated capacity only refers to the maximum weight your forklift can handle at a specific load centre. You can generally find the load centre of your forklift by calculating the distance from the vertical face of your forks to the load’s centre of gravity—on a standard 48” palette, this point is 24” away from the face of the forks. Just remember, that’s going to change if your load’s weight is unevenly distributed.

What Do I Do if My Hydraulics Fail?

Hopefully, you’ll never need to ask this question because you won’t wait for your forklift to fail before having it inspected and serviced. When it comes to forklifts, an ounce of prevention is worth several metric tonnes of cure—you don’t want to risk a workplace accident that could leave someone hurt (or worse).

But if the hydraulics in your forklift have failed and you’re having it serviced, keep these rules in mind:

- Remove the key and disconnect the battery before making any repairs.

- Never repair your lift in an environment where the atmosphere is flammable or combustible.

- Make sure there is adequate ventilation for fuel and exhaust fumes.

- Only use non-combustible solvents to clean your forklift.

- Under no circumstances should you ever move your body beneath a forklift.

Don’t Wait For Disasters

Hydraulic forklifts are useful in a wide variety of applications, but they require regular inspections and maintenance to operate safely and reliably. Know the parts of your forklift, and have them serviced by qualified professionals so your business can avoid hydraulic failures and workplace accidents.