When you own any type of vehicle or piece of heavy equipment, it’s always a good idea to familiarize yourself with how it works—but when it comes to forklifts, that knowledge is especially valuable. Learning more about the engine in your forklift will help you avoid common problems and know when it’s time to maintain your investment with professional forklift service.

At HardCo, we’ve worked with forklift engine types of all kinds. Let us tell you what you need to know about the engine in your forklift so you can get the most out of it, and contact us for assistance if you experience any issues.

Common Forklift Engine Types

There are countless forklift models out there, but most use one of four different basic engine types. Here’s a simple breakdown of each one and how it works:

Electric

Electric forklift motors use opposing magnetic fields produced by an industrial battery to move the rotors and create RPM. These motors typically have no transmissions or drive shafts; instead, the motor connects directly to the drive axle.

Pros & Cons: Electric forklifts are generally quieter than models with other engine types, and produce no tailpipe emissions. However, they may cost more up front and are often limited when it comes to their maximum load capacity. These types of forklifts also require the use of battery-charging stations to remain operational long-term.

Diesel

Diesel engines rely on internal combustion: the process of converting latent chemical energy into mechanical energy via small explosions, which move the pistons inside the engine cylinders to turn a crankshaft. In most internal combustion engines, these explosions are created by mixing the fuel with air, then compressing it and igniting it with a spark. However, since diesel is less combustible than propane or natural gas, the fuel in these engines is only injected after the air has already been compressed and heated, which helps the diesel ignite.

Pros & Cons: Diesel-powered forklift engines typically produce more torque at low RPM than electric versions, which puts less strain on the motor over time and increases the engine’s lifespan. However, the emissions produced by diesel forklifts often make them impractical for indoor applications, and they will likely become more expensive to operate in future as fossil fuel prices increase.

Propane

Propane forklift engines use much the same principle as standard liquified petroleum gas engines. A compressed mixture of air and fuel is ignited by a spark plug, creating combustion that moves the engine’s pistons. However, since propane is relatively clean-burning, forklifts that rely on it as a fuel source can generally be used indoors—except in situations involving food & beverage transportation.

Pros & Cons: Forklifts with propane engines are usually less expensive to purchase than electric or diesel varieties, and may outperform electric models—especially over long periods of heavy usage. However, rearward visibility may be limited while using these lifts, due to the placement of the propane cylinders they carry—and these cylinders need to be replaced regularly, which some owners may find inconvenient since handling propane can require specific safety training.

Natural Gas

Some forklifts with internal combustion engines rely on compressed natural gas (or CNG) as a fuel source. Just like in propane and petroleum engines, CNG is mixed with air before being compressed and ignited.

Pros & Cons: CNG forklift engines produce fewer emissions, and are relatively easy to refuel since the tanks can be refilled instead of replaced. At present, however, forklifts with natural gas engines are hampered by the lack of widespread CNG refuelling stations in most areas. For forklift owners without an abundant supply of CNG or the means to produce it themselves, these forklifts may not be practical for quite some time to come.

What Type of Forklift Engine Is Best?

When it comes to choosing a type of forklift engine, consider your needs. Here are a few good reasons for choosing each of the engine types outlined above:

- Electric forklift engines are excellent for indoor applications which require moving lighter loads.

- Diesel forklift engines are ideal for heavier lifting in outdoor environments.

- Propane-powered forklift engines are well suited to indoor and outdoor applications, as long as you are not working with food or drinks and have the resources to train your personnel on how to safely handle propane cylinders.

Natural gas forklift engines will likely make effective options in the future, when CNG becomes more readily available on a large scale.

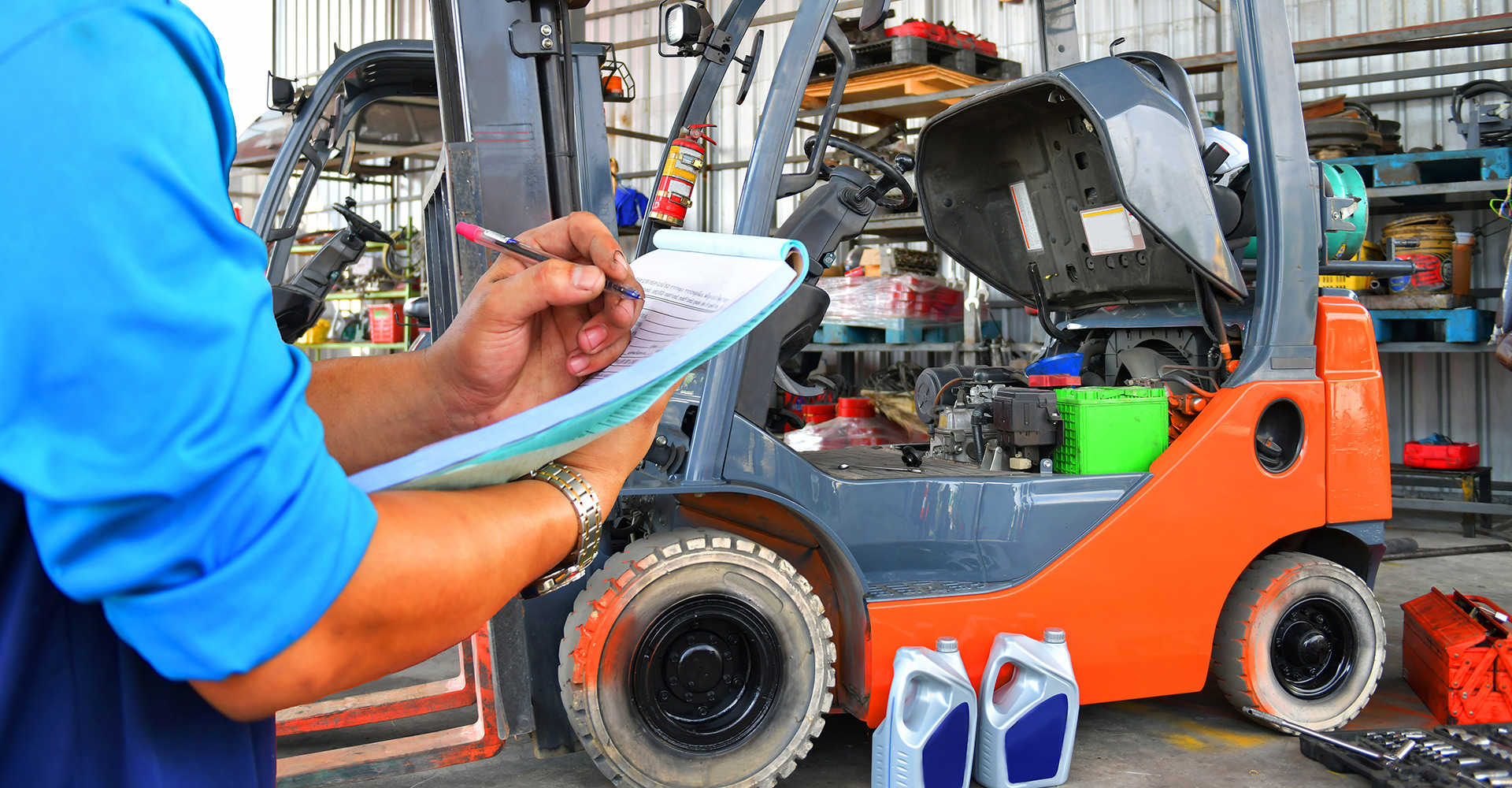

How to Maintain the Engine In Your Forklift

Maintaining your forklift’s engine is vital if you want to keep it performing optimally. Maintenance looks different depending on the engine type you have—for example, electric forklifts need to be charged regularly, while propane forklifts require frequent cylinder replacement. But all forklift engines using internal combustion technology need to have their oil changed, filters replaced, and spark plugs inspected on a regular basis—among many other routine tasks like tightening lug nuts and adjusting drive belt tension.

Consulting the owner’s manual in your forklift will provide you with a recommended schedule for professional maintenance—and the Canadian Centre for Occupational Health & Safety offers further guidelines on when and how to perform forklift maintenance. For more information about having your forklift’s engine serviced, contact us and speak with a team member who can answer your questions in detail.